About us

To become the best professional service provider in China for machinery field

|

To suit with market need and provide total solution to customer, Advanced Technology Department (ATD) was formed in 1990. ATD aims at providing more advanced machinery –3D Metrology System, Precision Measuring instrument, 3D Printing System, SMT Electronic Equipment and 3D Laser Welding machine etc.,and also provide the relevant professional training courses. Foresee the labor shortage, the increase of labor cost and the high demands on product accuracy; Pro-Technic established the Automation Department in 2008 to provide customers integrated solution of high precision machine with equipment and software. It perfectly match with growing concern for Industries 4.0. |

| In 1987, Pro-Technic formed the China Trade Department for developing the market in China. Now we have 20 branch offices and four Solution Centers all over China. As technology keep on improving and developing, machine reliability and maintenance are quite important. To ensure the service quality, Pro-Technic employs service engineer through serious selection and provide regular on the job and overseas training. Customer Service Department including Hong Kong and the Mainland staff comprises of more than 180 experienced engineers and are divided into several specialized sections. Customer Service Department aims at “Customer-Oriented, Efficient with Effective” provides professional advice and technological support to customers. To ensure the company overall service quality match with international standard, Pro-Technic got an ISO certificate in 1998 and adopted SAP as an ERP system in 2009 to further increase the operational efficiency and service quality. |  |

|

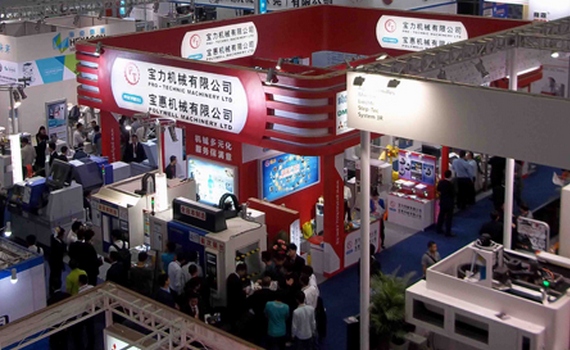

Pro-Technic actively providing high precisionmachines and advanced technology including ourown developed machines and MES to theindustry. Every year, Pro-Technic participatesover 10 public exhibitions, hold private show andtechnical week in Solution Centres; organizeseminar together with professional association tointroduce latest technology and machinery totheir members in order to keep pace with theirbusiness development; holds overseas studymission and technical forum regularly. Thosehelp to provide communication platform betweenmanufacturer and customer so that manufacturerknows more about customers’ concern andenhance confidence in products. Throughtechnical magazine, newspaper and Pro-Technicbimonthly news, latest machinery andtechnological information are conveyed tocustomers. |

|

|

|

|

|

|

FASTCELL flexibleproduction systems

|

Provide qualitymachinery andservices

|

GOM-3D OpticalScanner

|

|

Solution Centre

Solution Centre Service Hotline 400-889-8282

Service Hotline 400-889-8282