描述

Spindle headstock assuring high precision turning

• Rigidness and accuracy oriented construction are basic points required for precision turning of 2nd operation.

• Based on its tradition and experience, EGURO designed the spindle headstock with the construction that the spindle is supported by double ultra precision angular contact bearings both at the front and the rear.

• This is good against the load from axial and radial direction and accordingly the accuracy of less than 0.5μm is attainable for roundness and rigidness as well.

Linear turret tooling to minimize idling time

• Eguro, linear turret oriented, has adopted linear turret to the tooling of NUC ET-10EX. Tools are fixed, without turret index, and minimizes idle time. This is good for accurate positioning and is essential for high precision turning of 2nd operation, Slide rapid traverse is 15m/min. for both X and Z axes, by which high speed operation is achieved.

Stable positioning accuracy

• Closed loop by optical scale of 1 um resolution is standard specification for X axis, the slide of which is with carefully scraped grinding surface. Stable positioning accuracy is maintained from cold start.

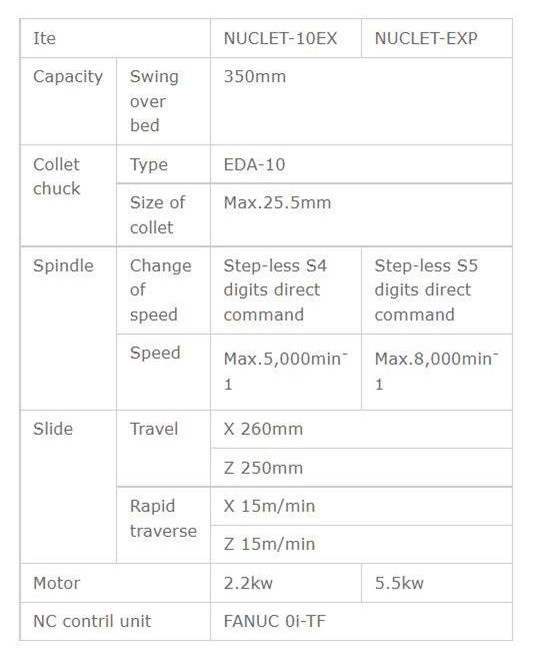

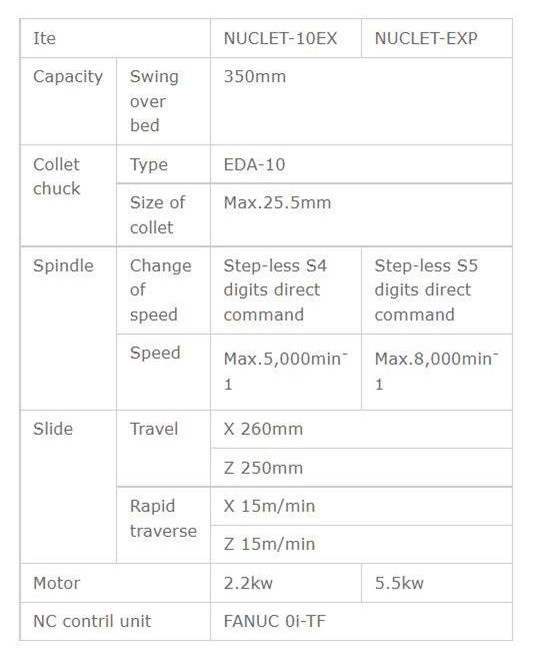

INUCL ET-10EXP for higher precision turning

• Spindle built-in motor of 10,000 rotation per minute is mounted, Optical scales, of 0,1 um resolution are adopted for both X and Z axes. Together with standard model NUCLET-10EX NUCLET-10EXP makes a line-up for customers’ selection.

Good operation ability

• The style is soft and round, which is warm and friendly to the operators. Handle run. newly adopted, is a function to check program by the trace of the tools moved as per program by manual pulse generator. Forward or backward direction. Interference or programmed moving of the tools can be checked before operation.CRT and operation panel are located at low position, in consideration of the operators’ working condition.

This upgrades the operation ability.