Description

Standard version:

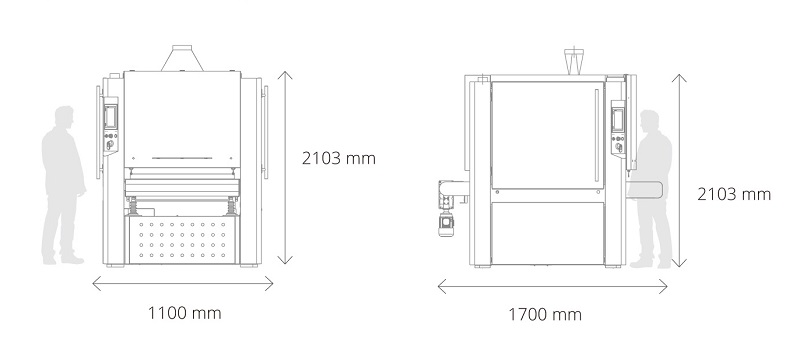

– Machine working width: 1100 mm.

– Efficient ergonomic operation through a user friendly Siemens HMI

(installed under a 45° angle for a clear view of the machining process).

– Vacuum table for machining smaller products (50 x 50 mm).

– The vacuum table has an integrated cleaning cycle.

– LED beam on the infeed side that indicates the machine status.

– Frequency-controlled motors for flexibility during the process.

– Easy to replace brush units.

– Various brush types are possible for multifunction use of materials.

– Automatic adjustable table height: 0 – 100 mm.

– Conveyor speed from 0.2 to 8 m/min.

– CE certified.

Applications and benefits:

– Contact time with brushes: 600 mm.

– The 4 brushes have a total of 15 m2 of abrasive agent.

– For the removal of burrs on laser, water jet, punched and cut products.

– Material that can be machined: stainless steel, steel, aluminium, copper, etc.

– The preliminary removal of large burrs and finishing of surfaces in one pass.

– Breaking edges/finishing of metal with a brush.

– Removal of the oxide skin with a special brush.

– Low tooling costs and very low energy consumption.

– Maximum user friendliness and optimal view of the machining process.